Aprilia RSV-R Mille 1000 (99-00) Rear Custom Brake Line Kit

Aprilia RSV-R Mille 1000 (99-00) Rear Custom Brake Line Kit is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Fast FREE Shipping over $99 (Continental US) and Low International Shipping Rates

Fast FREE Shipping over $99 (Continental US) and Low International Shipping Rates

- We offer Fast, FREE shipping within the continental US for orders over $99.00.

- For more information on shipping, including our low international shipping rates, see our Shipping Policy.

Expert Advice

Expert Advice

We are here to help you choose the best product for your ride. You can always Contact Us. We respond to all questions within a few hours during a business day or by the next business day.

Description

Description

Why Choose Core Moto Lines?

Core Moto SS performance brake lines are made in the USA using the highest quality materials and machinery available. We strive to make the best quality product on the market and are constantly looking for ways to make our brake lines better. The level of quality materials and processes used to make each Core Moto brake or clutch line is felt directly by the person operating the motorcycle they were installed on.

Core Moto brake lines are the most customizable brake lines on the market, ensuring you have a truly unique product that will stand out from the rest.

Core Moto brake lines are made in the USA and have a LIFETIME WARRANTY against leaks, breaks, ruptures and any type of failure of function.

Core Moto lines are made custom to each order and usually ready to ship same day.

Why Choose Stainless over Rubber hoses?

OEM rubber hoses expand and swell, especially under extreme braking conditions. This expansion results in what is often described as a spongy feel or brake fade. Most motorcycle manufacturers recommend that your OEM rubber brake lines be replaced every 4 years when used under normal conditions. Core Moto Performance lines are good for the life of the motorcycle.

Core Moto lines do not expand under pressure or fatigue. All braking input is transmitted from the master cylinder directly to the calipers, giving you complete control, feel and feedback from the final point in the braking system. Total brake response and performance is improved with this often overlooked yet simple modification.

Included in each kit

:Order invoice.

:Core Moto brake line retail packaging.

:Core Moto brake lines with proper lengths, banjo bend angles, mounting grommets and colors according to your model and order details.

:New low profile stainless steel banjo bolts with lightened heads.

:New copper crush washers.

:Installation and brake bleeding guide.

:Core Moto stickers.

High performance braking is not just for the race track!

Get more from your brake system with Core Moto Performance Brake lines

STEP 1 :Choose Your Line Color.

Core Moto Brake Hose.

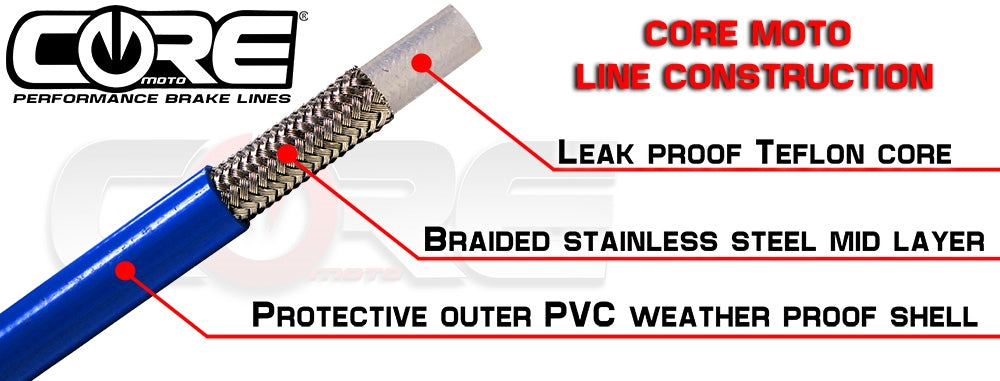

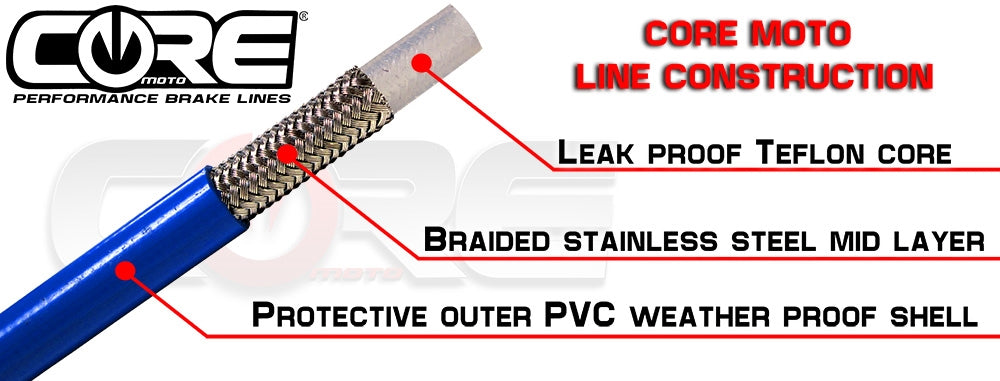

Core Moto stainless steel brake lines are made using only top grade materials and construction. Each line features an inner core Teflon® hose wrapped tightly in a cold drawn high tinsel 32 strand stainless steel braid. All lines are then coated with a flexible PVC outer shell for superior strength, corrosion resistance and abrasion protection. Available in 19 color options.

Line material from other companies may look the same but the real quality lies in the chemistry and composition of the materials being used. Our Teflon® core stainless steel lines can be bent 18,000,000 times before rupture compared to only 750,000 bends of the standard PTFE used by some other companies. Our Hoses have been batch tested to 18,000 psi without failure. (normal motorcycle braking pressure is 800 - 1,000 psi) Most companies only test assemblies up to to 5,000 psi. We choose to use line material that out performs industry standards.

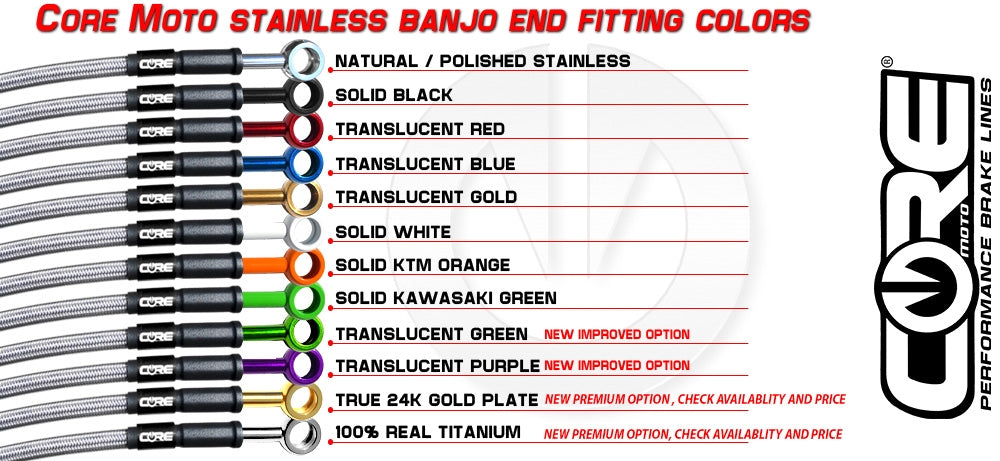

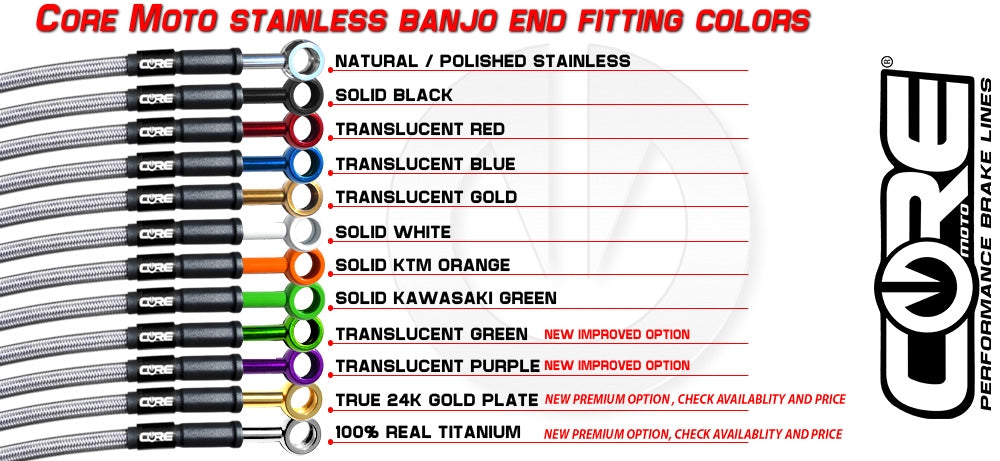

STEP 2 : Choose Your Banjo End Fitting Color.

Core Moto Stainless Banjo Fittings.

All Core Moto banjo fittings are CNC machined and polished high grade stainless steel. (NOT ALUMUNIM) Even our Colored banjo fittings are stainless. With ten different colors to choose from, we have the largest selection of color options on the market. Finding the right color option for your custom look has never been easier.

Core Moto color banjo fittings are NOT aluminum, they are NOT COLOR ANODIZED . So, color fade from sunlight exposure as seen in anodized aluminum banjos is not a problem with Core Moto brake lines. Our Stainless steel end fitting colors are achieved by a specially developed powder coat material and process specific to our application and product.

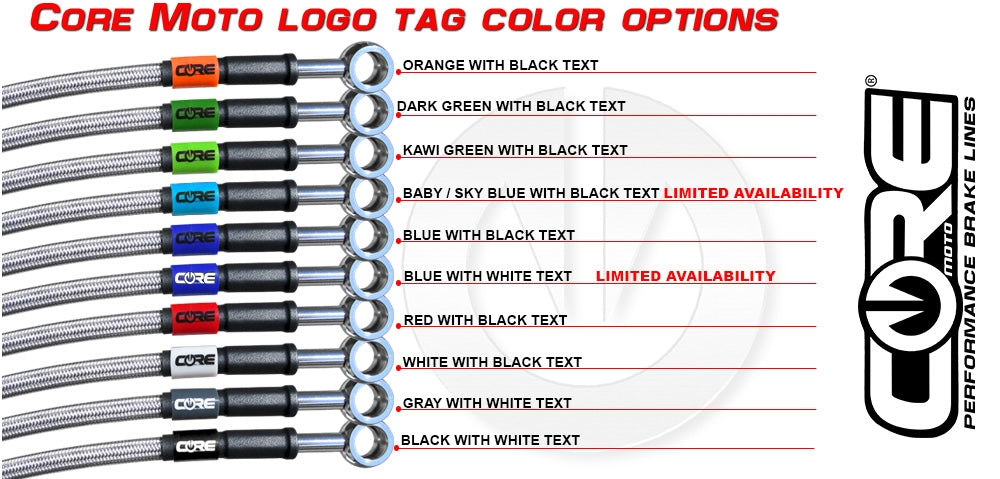

STEP 3 : Choose Your Logo Tag Color.

Core Moto Branding.

Here at Core Moto we are proud of our brand and the quality it represents, all lines come with a full lifetime warranty. Therefore we incorporate several unique identifiers into each brake line we make. The Core Moto name is stamped into the swage collar on every line we produce, this is what we need to see for warranty service. Additionally most of our banjo fittings will show a laser etched Core Moto symbol on the end. To complete the custom look Core Moto offers several different logo tag colors to choose from.

Blacked out Collars

For those that choose not to shine we have you covered, literally. Our "Black Out " feature will cover the collar with adhesive lined thermo formed covering, also required by DOT standards. This added feature COMES STANDARD on all lines we make at no additional charge. If you do not want this feature, you must request (no black out) in your order notes at time of purchase. Otherwise this covering can be removed by the end user if desired.

Hardware included:

All Core Moto Brake line kits come with CNC machined stainless steel banjo bolts and copper crush washers.

Our stainless banjo bolts have a low profile head with a lightened concave dish in the top for weight reduction and a nice finished performance look.

Line routing configurations.

(IMPORTANT FITMENT INFORMATION BELOW)

Unless stated in the product name above the main image, all line kits are for NON ABS equipped bikes.

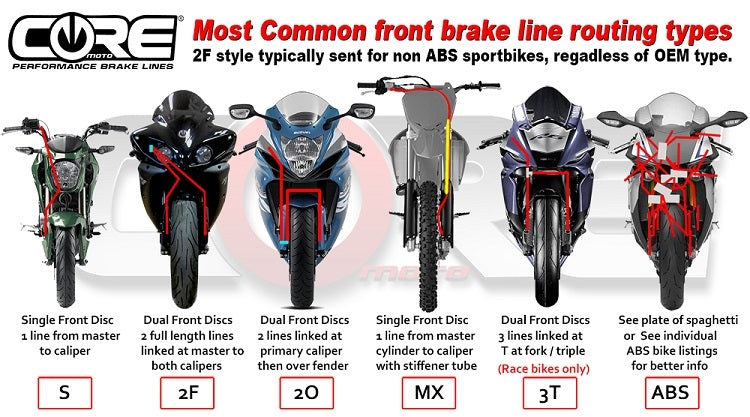

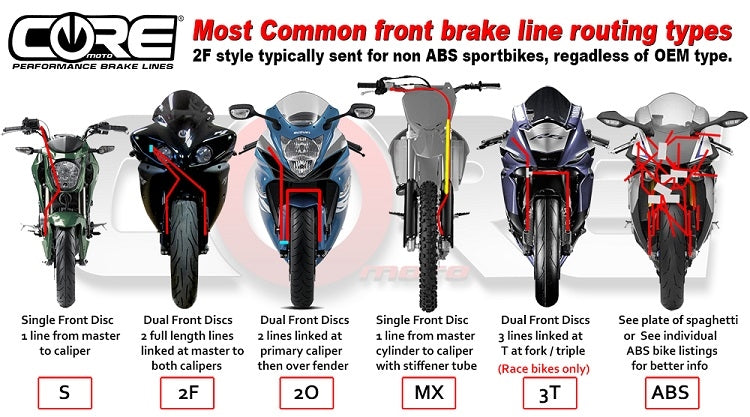

In most cases when ordering a front brake line kit for any dual front disc system, we will construct a 2F routing kit even if your bike was originally equipped with another type of system .

Our 2F and all other kits are designed to fit your specific model...we do not make

one size fits all brake line kits. Each brake line kit has been tested for fit and function on the motorcycle

model listed in the sale.

2F= As described above this layout uses 2 lines connected to the masher cylinder and delivers pressure to each caliper simultaneously for optimum breaking performance. This is the system we try to make for all applications, only if absolutely necessary for fitment reasons will we make another type of system.

2O= Over the front fender, this is typically a factory layout but can be requested on SOME motorcycles. This layout forces one caliper to serve as the primary caliper then transfers pressure to the secondary caliper. In most cases if your bike originally used this system we will replace it with the performance 2F system designed for your bike.

3T= One line from the master cylinder leading to a junction that branches 2 more lines to each caliper. In most cases if your bike originally used this system we will replace it with the 2F system designed for your bike.

STOCK LENGTH= Any time the term "stock length" is used in our descriptions or options, this means that the line kit you will receive will fit a specific motorcycle that is in stock condition and equipped with the factory brake system components. This term DOES NOT mean that the brake line kit we make is exactly the same dimensions as your OEM brake line. When we fit a brake line for a specific model we do not always make the line lengths, routing and end fittings the same as the factory rubber hoses. We measure, construct and catalog our line kits and fitment data in a way that we believe works best for our aftermarket brake lines on each factory model.

Modified bikes: Our line kits are designed to fit bikes as equipped from the factory, therefore certain modifications done to a motorcycle may affect line fitment. These modifications include, but are not limited to aftermarket, replaced or re positioned handle bars, risers, rear sets, calipers, caliper locators, master cylinders, extended wheel bases or any items that may interface with brake line mounting and routing. Also, bolt sizes and threads are not the same on all motorcycle brake components. Core Moto will send the correct bolts for orders based on OEM hardware the motorcycle requires unless requested by the customer. It is the customers responsibility to take all modifications into consideration before placing an order.

We construct all orders according to the options you choose when making your purchase. Unless requested we will use our build data we have on file for each model motorcycle when we build your line kit. We only accept returns if a mistake was made by Core Moto in the construction of the brake line. If you are unsure or have questions about fitment please call first, we can assist you and are happy to make custom brake lines to your specifications.

We recommend that all brake lines should be installed and bled by a qualified mechanic. Before operating the vehicle, the brake system should be cleaned and fully tested for proper function, steering and suspension clearance and inspected for any signs of fluid leakage.

Some motorcycles can use

up to 10 lines for a front and rear brake system, however this is not

common. If your application requires more than the most common 2

front 1 rear line set up, the

kit will be priced according to the total amount of individual lines

required. See pricing section for details.

Pricing is per line count 1,2,3,4,5..... This represents the amount of lines required for each system.

Below is an unsolicited review we found on YOUTUBE. With the permission of the publisher we have added it to our product listing so you can hear directly from a real customer about our product. This publisher has more videos showing the line installed on his ZX14 as well as reviews for different products from other manufacturers.

Thank you

No member of Core Moto's staff took part in making this review video. For actual technical information please refer to the product description text we have posted on our website.

Reviews (0)

Reviews (0)

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.